Injection moulding

Tailoring Material Properties

Futeon™ PLA is suitable for injection moulding on most existing production lines, requiring minor adjustments to processing parameters. The injection process can be optimised to achieve improved properties.

Additionally, Futeon™ PLA can be modified with additives or blended with other biopolymers to enhance flexibility, impact resistance, and thermal performance.

Injection moulding

The Strenghts of Futeon™

Offers excellent surface finish, transparency, colorability, and printability

Derived from renewable resources, Futeon™ helps reduce the environmental impact and lowers CO₂ emissions compared to fossil-based plastics

Supports mechanical and chemical recycling, enabling sustainable end-of-life options even for complex or blended consumer products, as well as industrial composting

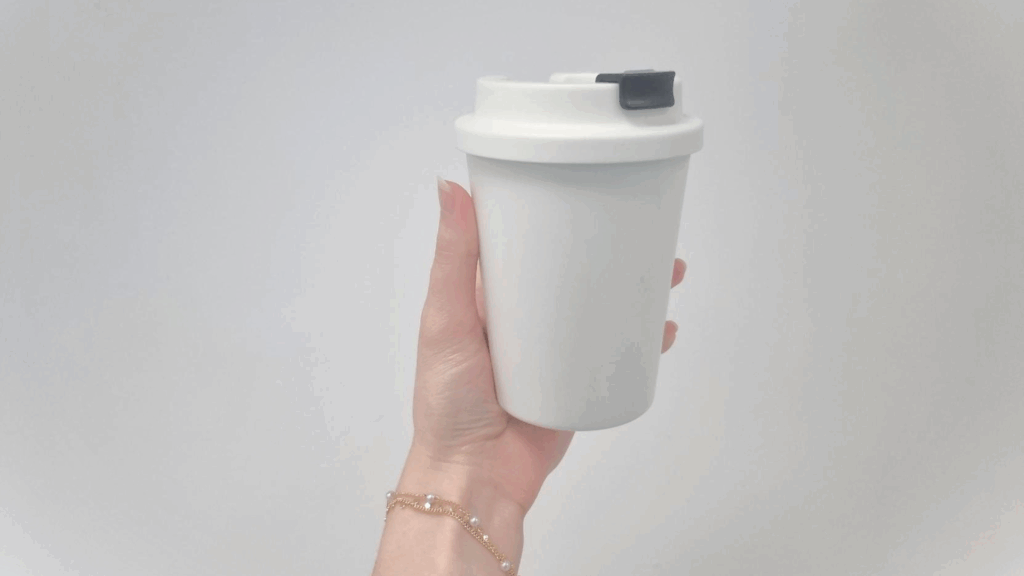

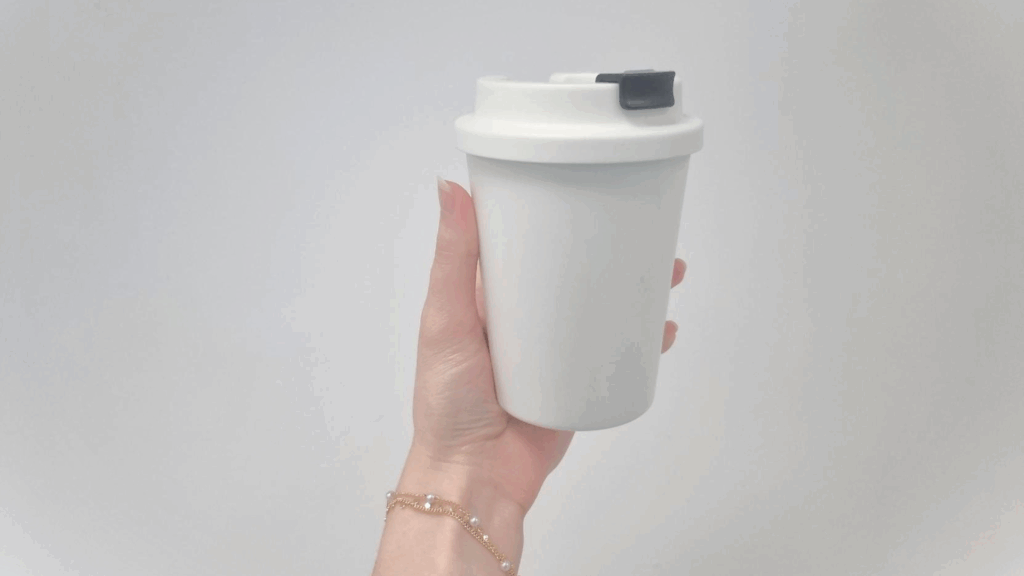

Futeon™ PLA can be used to deisgn reusable applications

Approved for food contact, ensuring consumer protection

Offers intrinsic rigidity and robust mechanical strength

Application examples

Reusable Tableware

Automotive components

Computer parts

Consumer Products