PLA vs Traditional Plastics

PLA comparison with traditional fossil-based plastics

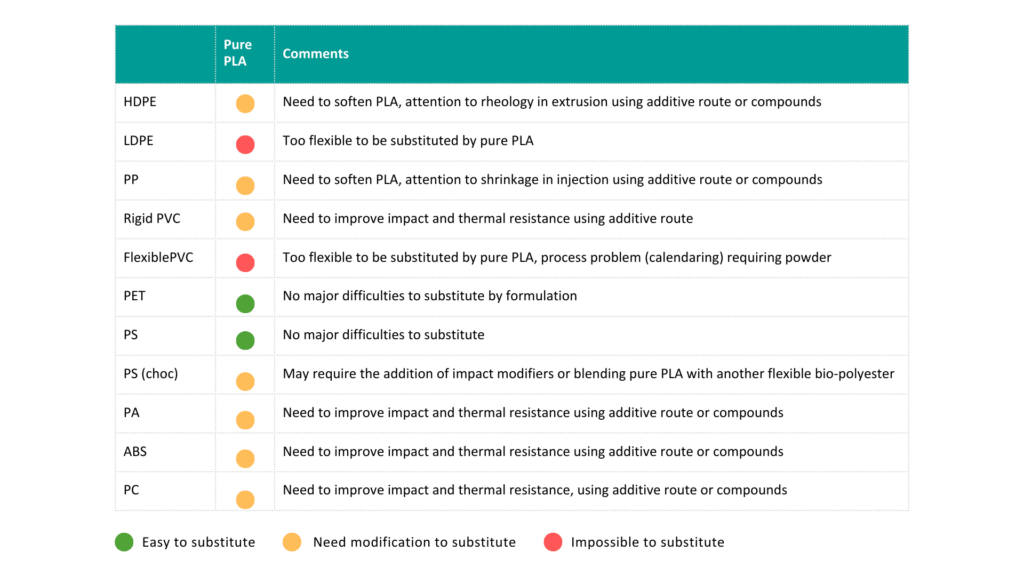

Pure PLA as a stand-alone resin can compete with PET and PS. Regarding HDPE, PP, rigid PVC, PS (choc), PA, ABS, and PC, PLA would need to be additivated and/or processed into a compound to achieve similar physical performances depending on the final application.

Limitations of pure PLA | Solutions | |

Brittleness | Impact modifiers, plasticisers | |

Low crystallisation rate/crystallinity | Nucleating agent | |

Limited heat resistance (if amorphous) | Fillers, nucleating agent, blends | |

Low hydrolysis resistance | Anti-hydrolysis agent | |

PLA vs Traditional Plastics

PLA technical limitations and solutions

Overall, while pure PLA has many key features, its medium heat resistance, brittleness, and sensitivity to moisture are limitations that must be considered when evaluating its use in various markets and applications. The development of new PLA-based compounds and the use of a broad range of additives allow for the improvement of the physical properties of pure PLA resins.

more specific questions?

We’re here to help! Please contact directly our technical team