Thermoforming

Seamless Processing

Futeon™ could be thermoformed on most existing production lines with minor modifications, making it a convenient option for manufacturers looking to switch to more sustainable materials. In general, pure PLA can be considered as a “drop-in” solution to PET and PS. More information about PLA’s possibilities as a substitute for fossil-based plastics is available here.

Thermoforming

The Strenghts of Futeon™

High gloss and excellent transparency for shelf appeal

Maintains flavor and aroma integrity

Approved for food contact, ensuring consumer protection

Optimized for smooth processing during the printing process for vibrant and high-resolution designs

Possible to seal the thermoformed PLA on various substrates under optimal conditions

Biobased, Futeon™ also enables industrially compostable and recyclable solutions with a lower CO₂ footprint than fossil-based plastics, supporting circular design goals

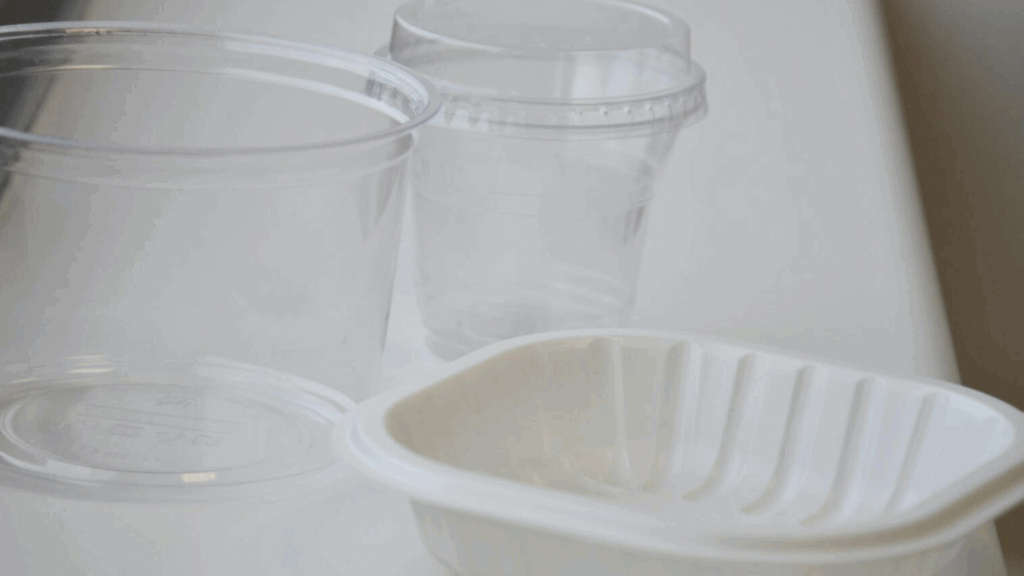

Application examples

Dairy and Dessert

Food packaging