End-of-Life Solutions for PLA

Futerro’s Approach to End-of-Life Management

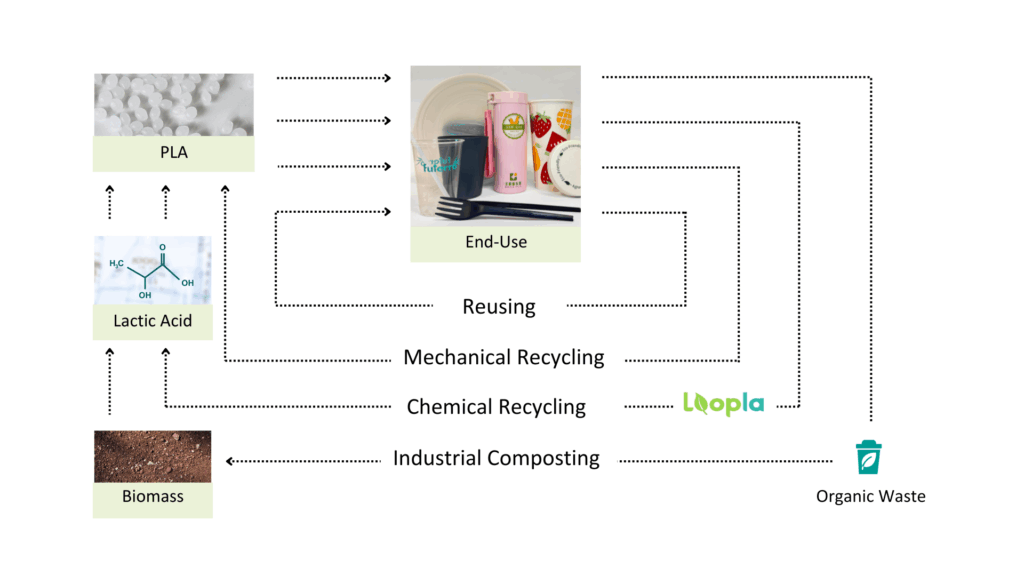

At Futerro, we recognize the importance of responsible end-of-life management for plastics, whether if they are derived from fossil-based or bio-based resources, and we acknowledge the need for the development of diverse end-of-life options. PLA is an innovative material with many approaches to end-of-life management, ensuring that our bioplastics are able to pave the way for circularity.

CHEMICAL RECYCLING

Loopla™: The Cornerstone of PLA Circular Economy

Our patented Loopla™ technology is a groundbreaking chemical recycling process, unique in its capacity to handle PLA-based products with unparalleled efficiency. Here’s why Loopla™ stands out:

We can recreate virgin quality Futeon™ PLA, making it the first truly biorenewable polymer.

We’re setting a precedent for a fully virtuous circular economy in the biopolymer market.

Loopla™ can process PLA based products contaminated with additives and/or colourants.

Loopla™ aligns with global government regulations and directives, ensuring our processes meet the highest standards.

Pioneering Circularity

Complementary End-Of-Life Options

While Loopla™ is our flagship solution, we also recognise the value of other end-of-life options; in our vision, it is not the material that must define the end-of-life, but its applications.

MECHANICAL RECYCLING

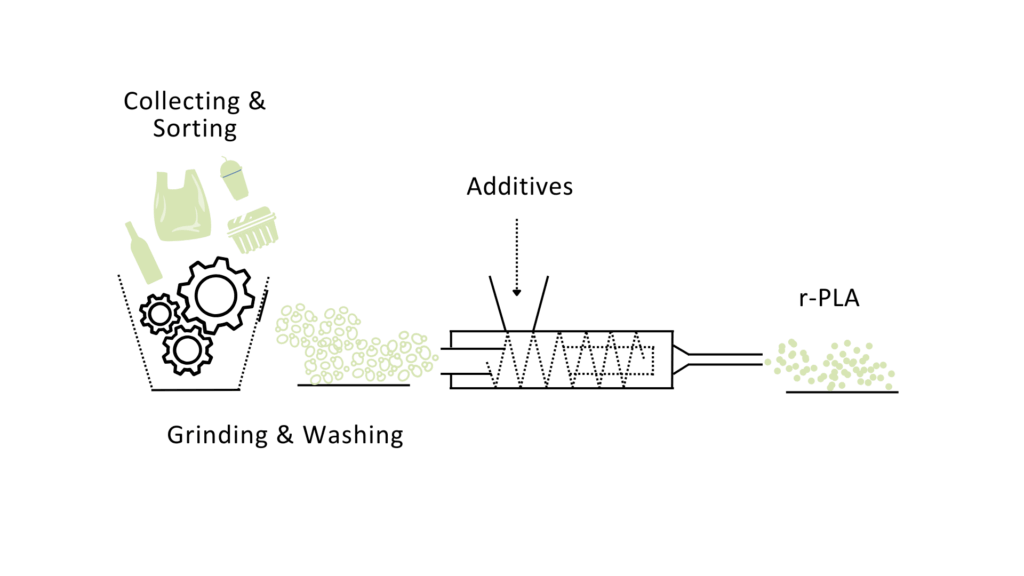

From Futeon™ to mechanically recycled Futeon™

The goal of mechanical recycling is to repurpose Futeon™ into recycled material. Mechanical recycling involves collecting, sorting, grinding, washing, drying, melting, and reprocessing plastic waste. However, this method can partially degrade polymer chains resulting in lower performances than virgin material.

Industrial Composting

From Futeon™ to plants

Industrial composting of PLA involves processing PLA waste on a large scale in specialised facilities. These facilities are designed to create optimal conditions for the biological degradation of PLA, turning it into high-quality compost by breaking it down into its simple organic components.

ENERGY RECOVERY

From Futeon™ to energy

To convert Futeon™ into energy, waste is used to generate heat, electricity or fuel through combustion, gasification and pyrolysis. In our vision, this is the last recovery option to be considered for the end-of-life treatment of PLA-based materials.